for youOur services

in detailLet's delve deeper:

FEASIBILITY STUDY:

All of the customer’s project ideas are listened to and analysed, offering a comprehensive consultancy service that ultimately aims to develop what is required at a systemic level, before proceeding to the prototyping phase.

HARDWARE DESIGN:

Designing a hardware system that meets the design specifications imposed by the customer, in order to draw up a functional circuit diagram and related BOM.

This service is also aimed at analysing existing schematics and designs, in order to make modifications and improvements, or to support the customer in the design service undertaken by itself.

SPICE ANALYSIS:

Electrical analysis of a schematic, drawn up internally by HTS or externally by the customer, along with the corresponding numerical and graphical results.

PCB LAYOUT DESIGN:

Design of the printed circuit board based on the schematic and BOM of the project in question.

The offered design service takes into account all project requirements in terms of currents, potential differences, operating temperatures, dimensional and mechanical constraints, IN/OUT interface positioning.

DEVELOPMENT OF THE PROJECT DATA PACKAGE:

Realisation of the final information package of the project required for the realisation of the finished product; this service is also offered for projects realised outside HTS.

POST LAYOUT THERMAL ANALYSIS:

Simulation of the behaviour of a PCB during its normal operation, in order to assess the presence of any dissipative criticalities, which may require a layout modification or the integration of dissipative supports.

POST LAYOUT ELECTRICAL ANALYSIS:

Simulation of a PCB layout in order to know the electrical parameters that characterise it such as: parasitic RLC values, single/differential impedance values, resonance phenomena, presence of unwanted electric/magnetic fields, goodness of transmission of HF signals.

NEW PRODUCT INTRODUCTION:

Working directly with the customer’s design team, we guide the new product through all stages, from the development phase to the finished product, to ensure high quality and innovative production processes.

BOX BUILDING:

HTS’s box building service aims to meet customer expectations in terms of quality and reliability for those who decide to fully outsource the production, not only of the electronic board but also of the various mechanical, metal and plastic parts of the finished product.

FAST PROTOTYPING:

We use advanced technologies to create prototypes with precision and efficiency, allowing customers to test them quickly and refine their concept. Our strong prototyping expertise accelerates the development process, reducing lead times and ensuring high-quality results.

IMPROVEMENT PROPOSALS:

Our team of experts proposes innovative solutions to improve the efficiency, functionality and sustainability of the prototype in terms of design, materials and manufacturing process helping to maximise the performance of the final product.

With our continuous improvement approach, we ensure that each iteration of the prototype is a step towards excellence.

SURFACE MOUNT TECHNOLOGY:

N°3 automatic production lines, with a production capacity of about 90.000 components per hour, allowing the assembly of 0050025 and BGA chips with a pitch of 0.15 mm

- Screen printer / Jet Printer

- SPI 3D

- Pick and place

- Forno a rifusione:

- 16 zone (8 top + 8 bot)

- Vacuum Technology

- Inertized in nitrogen

- AOI 3D

- X-RAY 3D

THROUGH HOLE TECHNOLOGY:

We perform manual and automatic THT assembly services with Sn/Pb and lead-free alloys

- N°4 Manual soldering stations

- N°1 Selective soldering

- N°1 Dual wave soldering

THERMAL STRESS:

We simulate and evaluate the effects that extreme environmental conditions have on electronic boards, to ensure the strength, reliability and durability of products under real conditions.

- N°2 Climatic chambers

- N°2 Baking oven

- N°1 Thermal shock chamber

PRE/POST ASSEMBLY CHECKS:

Pre/post assembly checks are the backbone of our quality assurance and are carried out both personally by our specialised operators and through advanced technologies, such as:

- SPI 3D

- AOI 3D

- FLYING PROBE PILOT V8 NEXT

- X-RAY 3D

FUNCTIONAL TESTING:

Based on the customer-defined testing procedure, we apply forced signals to the BUT (Board Under Test) and carry out measurements.

POWER TESTING:

Following the customer-defined testing procedure, we apply power signals to the BUT to bring the system into a steady-state operating condition in order to measure critical parameters, such as: Output power, THD, Power Factor, Efficiency, and much more.

IN-CIRCUIT TESTING:

Based on the availability of the ODB++ files, we offer functional testing of the BUT up to 100% coverage.

The Flying Probe performs the functional testing of the BUT by testing the individual component and subsystems, targeting any problems.

Testing equipment:

- Signal generator

- AC Source

- DC Source

- Power Analyzer

- Active load

- Oscilloscope

- Differential probes

- Current probes

- Flying Probe V8 Next

- Multimeters

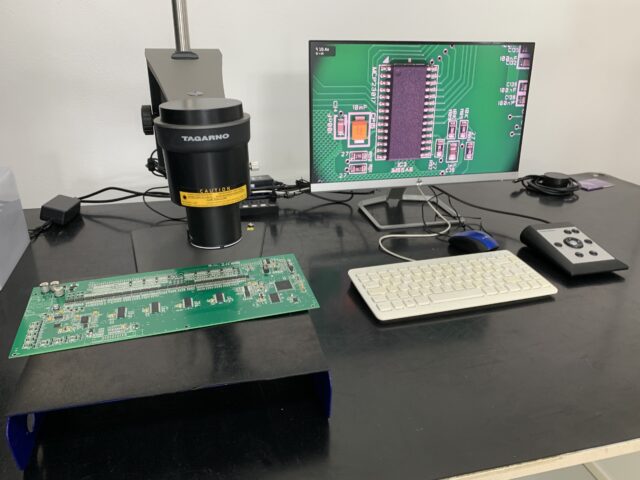

- Tagarno Microscope

- Vision Dynascope Microscope

- uC programmers

REVERSE ENGINEERING:

Refers to that set of analyses of the functions, uses, location, design, geometric and material aspects of an electronic board, the design of which is unknown.

It investigates the understanding of the functioning of an electronic board, applying a series of processes through which, starting from the single input data, the schematic and BOM of the board are obtained.

CONFORMAL COATING:

This is the application of a thin polymer, acrylic or silicone film to a printed circuit board with the aim of protecting the board and its components from the environment and preventing corrosion.

UNDERFILL:

It is the application of an epoxy material that fills the gaps between a chip and its substrate or a finished package and the PCB Substrate. The underfill protects electronic products from shocks, drops and vibrations and reduces stress on fragile solder connections caused by the difference in thermal expansion between the silicon chip and substrate.

REBALLING:

Reballing is a technique that allows the rebuilding of the bga chip by performing the removal of the bga from the PCB, cleaning the remaining solder residue on the pcb, and rebuilding the bga by placing new solder balls on the bga.

POTTING:

A process of partially or entirely filling an electronic component or assembly into an enclosure with a resinous material such as silicone for the purpose of providing protection, electrical insulation and heat dissipation.

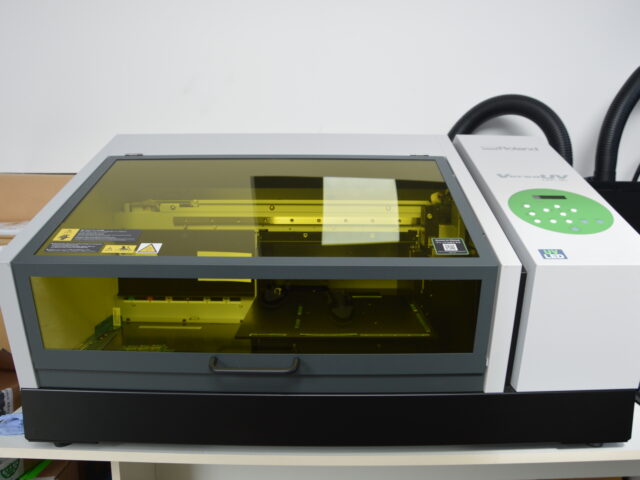

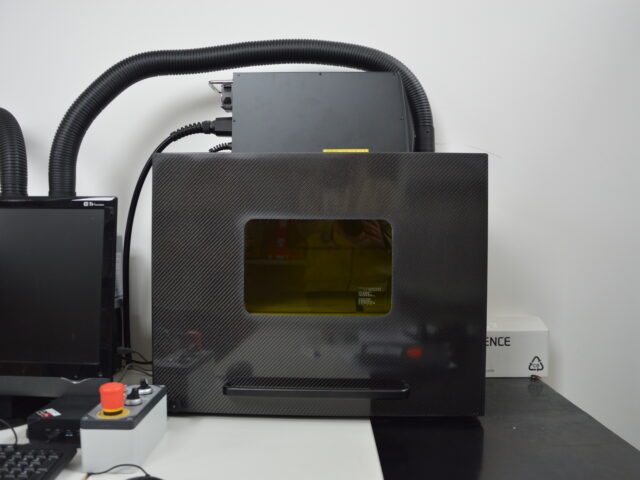

MARKING:

Through the use of two different marking machines, of which one is a laser and one an ink-jet machine, we offer a complete marking service useful both for those who simply want to engrave their logo on PCBs and for those who need to serialise them via alphanumeric code or QRCODE.

PCB WASHING:

This is a very useful practice to remove solder paste residues from any type of stencil and pcb, as well as to remove glue residues, fluxes and contaminations due to the handling or production of SMT or THT boards.